Flexible fireproof cables, also known as "inorganic mineral insulated cables", are currently developing rapidly in China because they are softer than mineral insulated cables and are easier to install and lay.

1. Product model of flexible mineral insulated fireproof cable

BTTW Copper core corrugated copper sheath Flexible inorganic mineral insulated fire-proof cable, rated voltage 750V.

YTTW Copper core corrugated copper sheath Flexible inorganic mineral insulated fireproof cable, rated voltage 750V.

YTTWG copper core smooth copper sheath, flexible inorganic mineral insulated fireproof cable, rated voltage 500V.

YTTWV copper core corrugated copper sheath, PVC outer sheath, flexible inorganic mineral insulated fireproof cable, rated voltage 750V.

DW-YTTWY copper core embossed copper sheath, low-smoke halogen-free polyolefin outer sheath, flexible inorganic mineral insulated fireproof cable, rated voltage 750V.

Flexible mineral insulated fireproof cable flexible fireproof cable manufacturer inorganic mineral insulated cable yttw flexible fireproof cable flexible fireproof cable wholesale

Flexible fireproof cable price How much is flexible fireproof cable professional manufacturer of flexible fireproof cable

Flexible mineral insulated cable BTLY isolated fireproof cable Mineral insulated cable Flexible fireproof cable

Mineral insulated flexible fireproof cable RWTZ YTTW BTTRZ BBTRZ flexible mineral insulated fireproof cable

Flexible cable Fireproof cable Mineral insulated cable

Flexible mineral insulated fireproof cable yttw flexible fireproof cable Flexible mineral insulated cable

Flexible fireproof cable standard Flexible fireproof cable installation

Flexible fireproof cable Flexible fireproof cable model Flexible fireproof cable standard Flexible mineral fireproof cable Flexible mineral fireproof cable

The third generation of flexible fireproof cable Flexible fireproof pre-branch cable High flexible towline cable

Flexible drag chain cable Flexible fire-resistant cable Flexible cable Flexible mineral insulated cable

2. Advantages of flexible mineral insulated fireproof cable products

1. Excellent fire resistance: the fire resistance grade not only meets the national standard GB12666.6 Class A 950℃, 90min, but also meets the British BS6387-1994 A class 650℃ 3h; B class 750℃ 3h; and C class 950℃ 3h Test requirements; at the same time, it can withstand water spray and mechanical impact during combustion;

2. Long continuous length: whether it is a single-core or multi-core cable, its length can meet the power supply length, and each continuous length can reach 1000m;

3. Large cross-section: single-core cable cross-section up to 1000mm, multi-core cable cross-section up to 240mm;

4. Good flexibility: the cable can be coiled on the cable reel, the bending radius is ≤20D, (D is the outer diameter of the cable);

5. Smokeless and non-toxic during combustion: Inorganic materials (non-combustible) are used for insulation, which will not produce any harmful gas during combustion, and will not cause secondary pollution. It can be called an environmentally friendly green product;

6. Large overload capacity: The cable not only has a large current carrying capacity, but also has a large overload capacity. According to the wiring instructions, usually the surface temperature of the cable is ≤70℃. If the wiring is not touchable or in contact with combustible building materials, the temperature of the cable sheath can be increased to 105℃. The long-term working temperature of the flexible fireproof cable can reach 250℃ when overloaded. ;

7. Corrosion resistance: Organic insulated fire-resistant cables sometimes need to wear plastic pipes or iron pipes, plastic pipes are easy to age and become brittle, iron pipes are easy to rust, fire-resistant cables with copper sheath do not need to wear the pipe, and the copper sheath has good corrosion resistance;

8. Good shielding performance: when fireproof cables are laid in the same shaft with information and control wires, they will not interfere with the information transmitted by the signal and control wires and cables under the shield of the copper sheath;

9. Safe and reliable: the fireproof cable can supply power normally in the flame, start the fire extinguishing equipment, reduce fire loss, and is particularly reliable for personal safety. Its copper sheath is a good conductor and a good grounding PE wire, and it continues to the full length of the cable. , Which greatly improves the sensitivity and reliability of grounding protection;

10. Long service life: Inorganic insulating materials have high temperature resistance and are not easy to age. Their service life is many times longer than that of organic insulated cables. Under normal working conditions, their service life can reach more than one hundred years;

11. Simple installation: the transportation and installation of flexible fireproof cables including installation accessories are similar to ordinary cables, which is relatively simple;

12. Low installation costs: Flexible fireproof cables have advanced manufacturing technology and simple installation. Under the same conditions, their overall costs are significantly lower than those of mineral insulated cables.

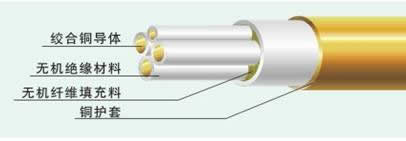

3. Flexible mineral insulated fireproof cable structure

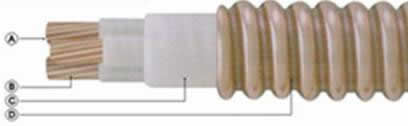

According to the needs of the cable application, the outer copper sleeve can be welded longitudinally without embossing

A. Conductor: stranded copper conductor; B. Insulation: synthetic mica tape; C. Filling: inorganic material; D. Copper sleeve: longitudinal clad welding and embossing

1. Conductor: stranded copper wires; 2. Insulation layer: high temperature resistant, non-combustible inorganic insulating material; 3. Copper sheath: longitudinally clad welded and embossed; 4. Outer sheath: low-smoke halogen-free material

4. Application range of flexible mineral insulated fireproof cable

1. Power supply for fire-fighting equipment and fire-proof elevators in various buildings

2. Power supply for equipment and lighting systems in important buildings or densely populated buildings

3. Places with high ambient temperature, such as steel plants, smelters, glass factories, etc.

4. Important flammable and explosive occasions, such as power supply for petrochemical, coal mine and other equipment

5. Places that require special cleanliness, such as power supply equipment such as hospitals and food factories

6. Power supply for important military, national defense, aviation, and satellite base equipment

7. Power supply for important equipment in power plants and nuclear power plants

5. Flexible mineral insulated fireproof cable and cable laying